Manufacturing and Distribution

With Industry 4.0, empower your team to work smarter, not harder

Schedule DemoCreating a Data Driven Culture with Smart Manufacturing at Radiaant

- $1M year on year savings with services and product engagement

- 20% increase in throughput/uptime with real-time visibility across the factory floor

- 80% of manual data analysis was reduced with lower dependency on data teams

Industries that we support

Heavy machinery is subject to normal wear and tear making it essential to implement a robust equipment management and maintenance approach. Our DataOps solutions create a culture of proactive maintenance in place of reactive maintenance. Gain access to real-time production data that allows you to track the progress of industrial equipment, effectively manage tools, ensure tool calibration, and efficiently handle inventory replenishment requests.

-

With asset utilization and monitoring smart tools, managers can proactively replace them before breakdowns occur

-

Enable the application of predictive maintenance in daily operations with accurate data leading to cost savings

-

Produce quality products with thorough quality inspections consistently with real-time data

Leveraging DataOps solutions bring significant benefits to the Make-to-Order industries like the food and beverage industry, aligning with their need for precise operations and quality control. Food and beverage manufacturers can capitalize on features like end-to-end operational visibility, real-time temperature data, line balancing for production status monitoring, supplier management, and other critical metrics.

-

Enhance quality control with quality inspections by utilizing IIoT sensors to identify and analyze potential hazards

-

Integrate workflows, connect systems, and production planning to optimize operations and achieve higher overall equipment efficiency

-

Enable line balancing for product stock tracking and leverage expiration date alerts for warehouse managers, preventing overstocking, minimizing waste, and saving costs

Real-time data is crucial for accurate demand forecasting and inventory management in the fast-changing fashion industry. Our DataOps solutions streamline production planning and schedule inventory management for efficient asset utilization, providing real-time visibility and operational efficiency across the entire supply chain ensuring quality products are dispatched through rounds of quality inspection with various quality metrics. Gain control and agility to create an edge in the industry.

-

Manage dynamic materials, vendors, line capacity, and quality process change with every order

-

No more disconnected view of the manufacturing process due to legacy systems

-

Put an end to unreliable manual and faulty processes, and promote cross-functional teamwork to eliminate any silos within the team

Key challenges for Distributors are demand planning and forecasting, fluctuating market trends, evolving consumer preferences, and inventory management. Our DataOps solutions leverage advanced analytics and machine learning algorithms to analyze historical data, real-time data and predictive analytics to analyze demand patterns, lead times, and supplier performance.

-

Support and streamline scheduling

-

Improve visibility and warehouse efficiency by proactively identifying potential stock outs, and adjust production schedules

-

Analyze customer data, purchase history, and preferences, companies can segment their customers into distinct groups and tailor their products

In order to maintain a competitive edge, medical device manufacturers must optimize their operations by leveraging current data and automating essential processes. Our DataOps solutions offer timely insights into device tracking, quality inspections and regulatory compliance, empowering manufacturers to stay at the forefront of the industry.

-

Be adept with regulatory compliance including safety standards and quality control metrics

-

Minimize product recalls and track devices by their batch number, lot number, or serial number to systematize operations

-

Facilitate cross-functional automation, seamless data sharing, and mobile access to files and documents

The automotive manufacturing industry aspires to deliver high-quality vehicles and parts with end-to-end traceability while preventing recalls. Alternative to the traditional paper-based processing, manual storage or retrieval system, and lack of real-time data from the final product, our DataOps solutions aim to streamline production and optimize operations with predictive maintenance based on IIoT connectivity tools.

-

Get a holistic end-to-end real-time view of your operations with configurable dashboards

-

Efficient line balancing for the vehicles ready to be finalized without halting the production

-

Enhance resource utilization with preventive and predictive maintenance to enable higher uptime and predict malfunctions in the product beforehand

Aerospace supply chains encounter multiple challenges, including high production demands, real-time governance requirements, quality control, and cost pressures. With our DataOps solutions, supply chains can leverage production planning and balance the lines, adapt to changing demand, implement end-to-end quality management, and enhance operational efficiency.

-

Centralize data collection with a single source of truth across your entire production process

-

Leverage robust real-time production visibility and tailor-made operational dashboards for enhanced insights

-

Achieve error-proof operations and real-time defect tracking with human and process data. Streamline inputs using connected devices for enhanced efficiency.

It’s paramount for chemical manufacturers to meet their goals for product quality, regulatory requirements, and monitor inventory levels, all while staying profitable. Our DataOps solutions provide a one-stop shop for streamlining data, giving manufacturers the insights they need to make informed decisions.

-

Ensure compliance with agencies like the Environmental Protection Agency (EPA), Food and Drug Administration (FDA), Good Manufacturing Practices (GMP)

-

React promptly to energy price fluctuations with agility and flexibility

-

Monitor carbon emissions with ESG monitoring

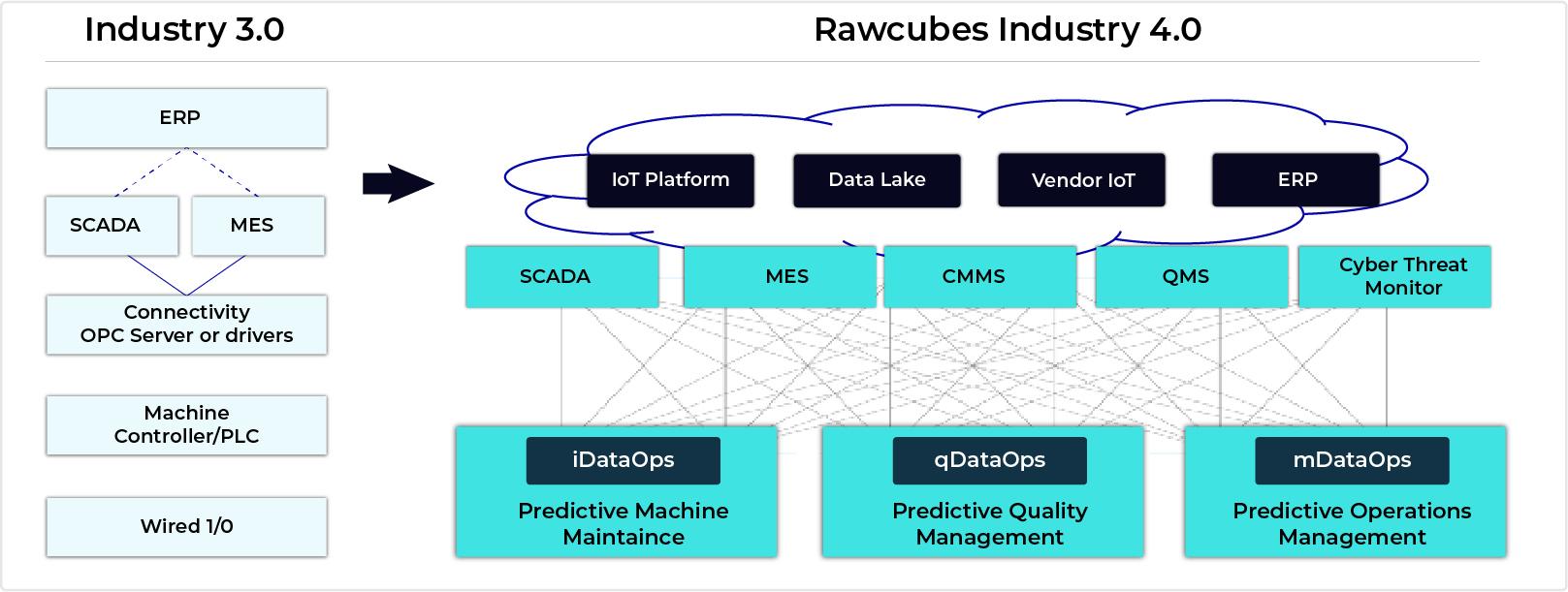

Manufacturing Operations of the Future

The manufacturing industry is undergoing a major transformation driven by data. Manufacturers are now leveraging the power of real-time data and analytics to optimize operations, reduce downtime, increase productivity, and improve product quality. Our DataOps solutions provide the quickest path to becoming Industry 4.0 and achieving a data-driven approach.

Our DataOps Solutions

We assist you in visualizing critical insights in real-time, so you can spend more time where it matters!

Data-Driven Assessment

In the ever-changing manufacturing landscape, it's crucial to have objective insights that help with decision-making, performance tracking, and regulatory compliance. Grafine' Data-Driven assessment is designed for manufacturers to identify and solve problems related to production, personnel, processes, and data-driven solutions.

Bottlenecks we address:

- Lack of data culture practices to enable Industry 4.0 in manufacturing

- Lack of real-time visibility and monitoring across the production processes

- Absence of proactive equipment maintenance strategies and predictive analytics

- Increase real-time visibility and monitoring of the production process

- Improve inconsistent quality control due to variations in raw materials, equipment, and personnel

- Ineffective eco-friendly manufacturing practices to minimize environmental impact

By leveraging our expertise, manufacturers can unlock their full potential and achieve success in a rapidly evolving industry.

Customer Success Story

Learn how our customers are finding success with our DataOps solutions

Get Started with a Complimentary Demo

Propel your business forward while streamlining your data efforts. DataBlaze saves countless personnel hours, drives more profitable decisions, and breaks down data siloes. Discover the DataBlaze difference today by booking a complimentary demo.

Book Demo